The condominium developer could not get the necessary permits for operation because the two building elevators would not run on the building’s emergency back-up generator. The problem was originally diagnosed as excessive voltage drop between the main service entrance in the basement and the tenth floor motor room. The technicians involved spent a lot of time and money trying to fix this presumed problem which had been incorrectly diagnosed. Among the solutions tried were: Adjustment of the transformer taps to +5 percent, replacement of the transformer with a model with a lower impedance model, and installation of an electronic tap switching regulator. A 450 kw emergency generator was even brought in for testing to see if it would be necessary to replace the existing 175 kw unit.

All of these attempts had some limited success, but none offered an acceptable solution.

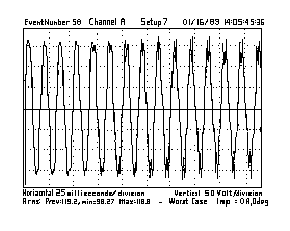

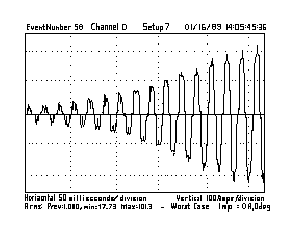

A consultant used a power monitor to evaluate the quality of the voltage and current supplied to the elevator motor. Figure 1 shows the current swell during motor startup, while Figure 2 reveals the effect of the current demand on the voltage.

Using the power monitor was essential to uncover the real problem. Two factors became evident: First, the true RMS voltage reported by the monitor showed that the values measured by the less accurate average reading DVM’s were misleading. The actual voltage drop was not as severe as first indicated. Second, analysis of the current and voltage waveforms (both visually and using harmonic analysis) showed that harmonic distortion, not low voltage, was the real source of the problem. The level of the fifth and seventh harmonics in the voltage waveform was due to the reactance of the generator windings in response to nonlinear current demand from the elevator motor controller. A circuit in the motor controller was sensitive to harmonic distortion at these frequencies, mistaking them for a phase rotation error. The solution was achieved by replacing this circuit at a cost of a few dollars.