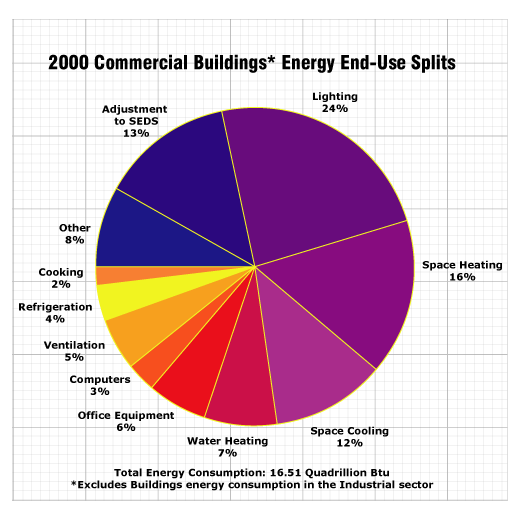

Utility energy and demand costs have a direct impact on a company’s bottom line. In fact, a typical commercial or industrial facility can save from 10% to as much as 35% annually on energy costs by implementing a comprehensive energy management plan. And while each facility will require an organized approach to recognize those savings, facilities first need to understand their power consumption, location of major loads, electric demand usage patterns, and associated costs.

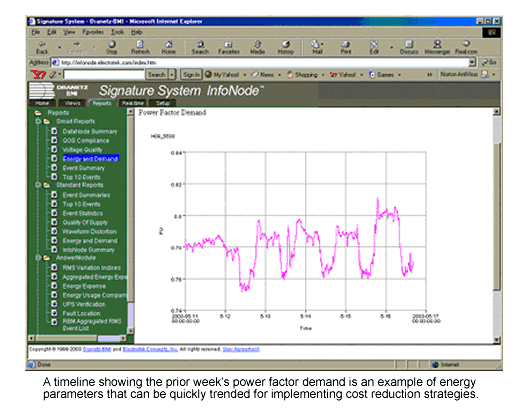

The cost of energy is one of the most commonly mismanaged expenses, regardless of a company’s size or the industry represented. Often, energy is purchased in one department, consumed in another, with energy management systems operated and maintained by still another. Since each facility’s energy situation is dynamic and interdependent, it requires continuous monitoring and management action to avoid escalating costs. The web-based Signature System™ enables users to continuously monitor and store power consumption and quality information in real time-to capture those savings and improve profitability. Customers use the System for:

- Power cost management: By looking at time of day, peak load and aggregated energy usage, customers can reduce their costs by rescheduling loads, making sure unneeded equipment is shut off when not in use, or installing energy-efficient equipment. Historical load profile data can be used to develop price/risk curves for evaluating energy purchase agreements.

- Power factor: Many customers pay a penalty to the utility for inefficient use of energy, or the ratio of power consumed to power delivered. Monitoring is a necessary tool for understanding the processes within a facility that impact power factor, to improve energy efficiency and reduce or eliminate any surcharges.

- Curtailment Rate Structure: Many customers have agreed to reduce (curtail) load at the request of their utility supplier in exchange for lower energy rates. Plus, non-essential loads can be shed or distributed generation brought on line to reduce consumption and/or participate in utility-sponsored demand reduction programs. Monitoring can help determine which loads on which circuits can be curtailed, as well as to certify compliance with curtailment requests.

- Allocate Costs and Perform Activity-based Costing: Track energy-related costs by department, tenant or process. Use the Signature System’s Energy Usage and Expense Reporting AnswerModule® to track, compare and document those costs against scheduled rates, and from one time period to another.

- Load profiling: Adding or upgrading equipment, computers and processes will impact the power requirements of a facility. Monitoring the existing load on circuits lets you know the impact of those changes and how much new load can be added to an existing circuit or facility.

- Lost power costs: Improper load balance grounding may not always be obvious. By monitoring, lost energy can be identified and minimized.